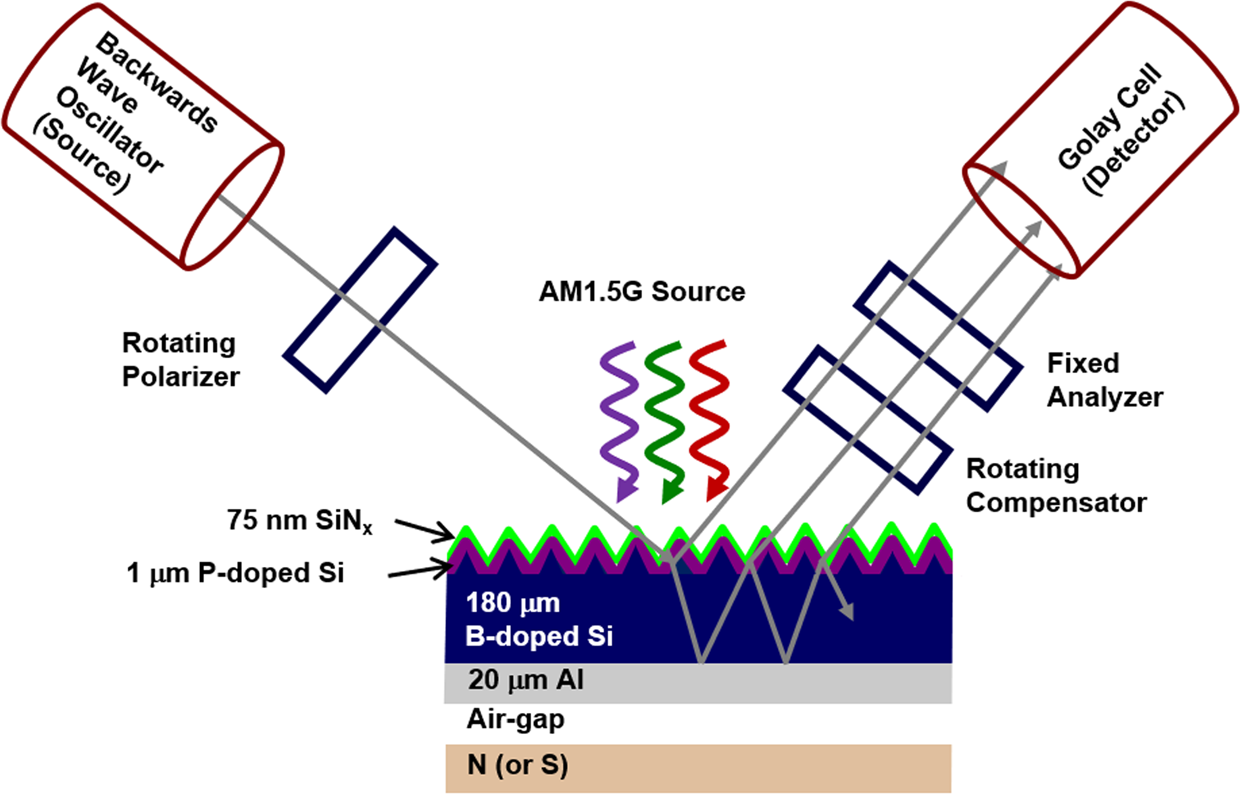

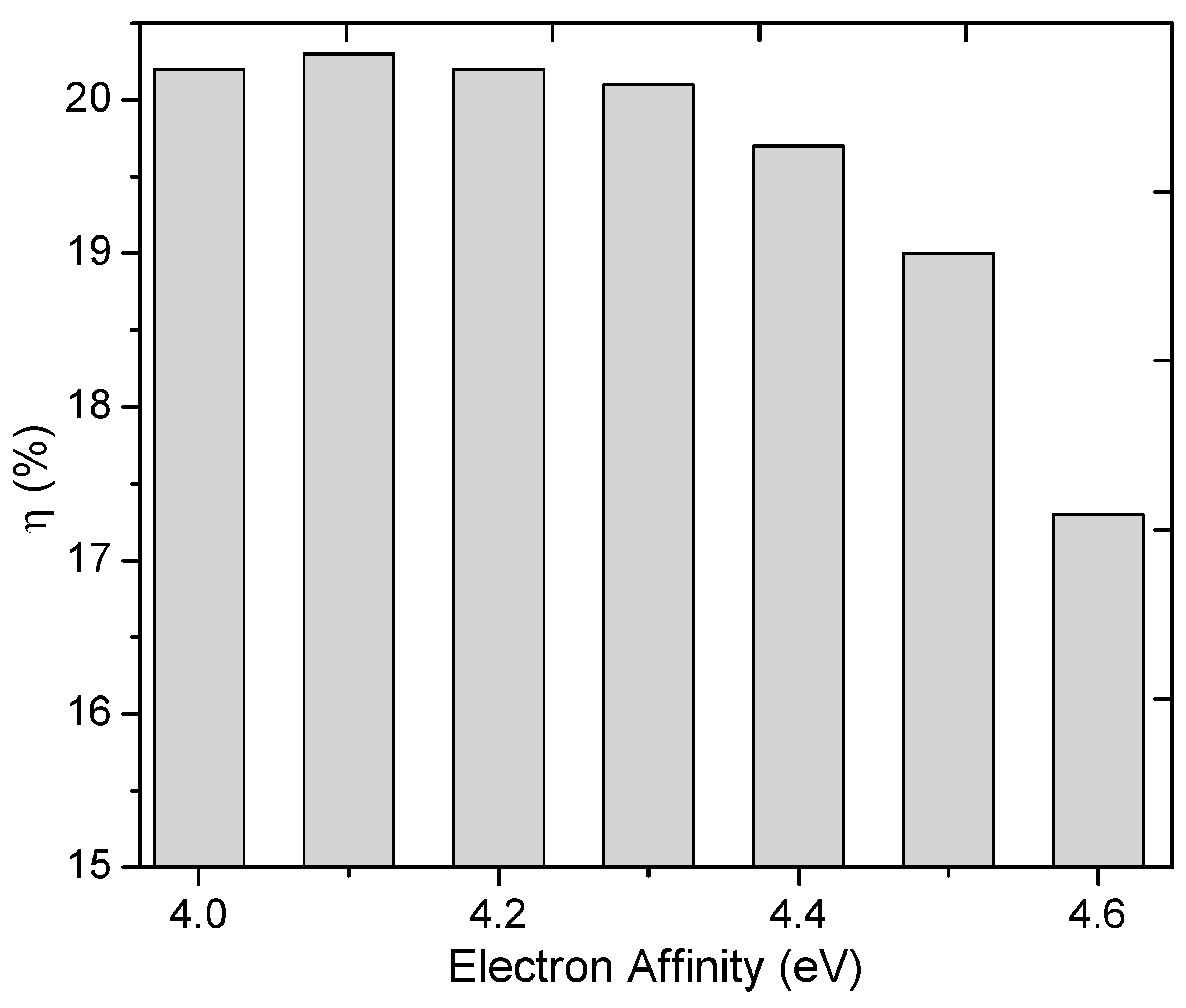

We chose three different gases as ambient gases during the firing process. In this paper, the effect of the firing ambient during the metallization process on the formation of Al rear metal was investigated. N2 - For rear metallization with Al paste, Al back contacts require good passivation, high reflectance, and a processing temperature window compatible with the front metal. © 2015 Materials Research Society of Korea. T1 - Effects of firing ambient on rear metallization for silicon solar cells The optimized temperature with oxygen flow shows an absolute efficiency of 19.1% at PC1D simulation.", It was found that the presence of oxygen during the firing process influenced the uniform back surface field because the organic materials in the Al paste were efficiently burned out during heating.

We calculated the efficiency with obtained the back surface recombination velocities using PC1D simulation. The oxygen ambient plays an important role in the burn-out process. In this study, we described the mechanism of burn-out of organic materials in Al paste during the firing process. To determine the effect of the ambient on Voc, the suns-Voc tool was used. Using SEM, we observed the formation of a back surface field in N2, O2, and Air ambients. The optimized temperature with oxygen flow shows an absolute efficiency of 19.1% at PC1D simulation.Ībstract = "For rear metallization with Al paste, Al back contacts require good passivation, high reflectance, and a processing temperature window compatible with the front metal.

For rear metallization with Al paste, Al back contacts require good passivation, high reflectance, and a processing temperature window compatible with the front metal.

0 kommentar(er)

0 kommentar(er)